Manufacturing excellence that’s decades in the making

It all started in Building 6. That was the site of Amgen’s first fully dedicated manufacturing facility for Amgen’s first biologic medicine, used to treat a debilitating blood disorder.

Manufacturing staffers overseeing a filling machine to dispense final, formulated product into vials ready for distribution.

Construction began in 1986 in Thousand Oaks, California

Two years later, its doors opened. The building contained two large and two small stainless steel tanks. Inside these walls, three thousand plastic roller bottles filled with red liquid turned once every minute. It was built to produce a total of just 200 grams of biologic medicine per year.

Fermenters in Building 6.

Today Amgen makes more than a dozen medicines across multiple therapeutic areas —

and its highly sophisticated global manufacturing network has helped it reach millions of patients with its medicines.

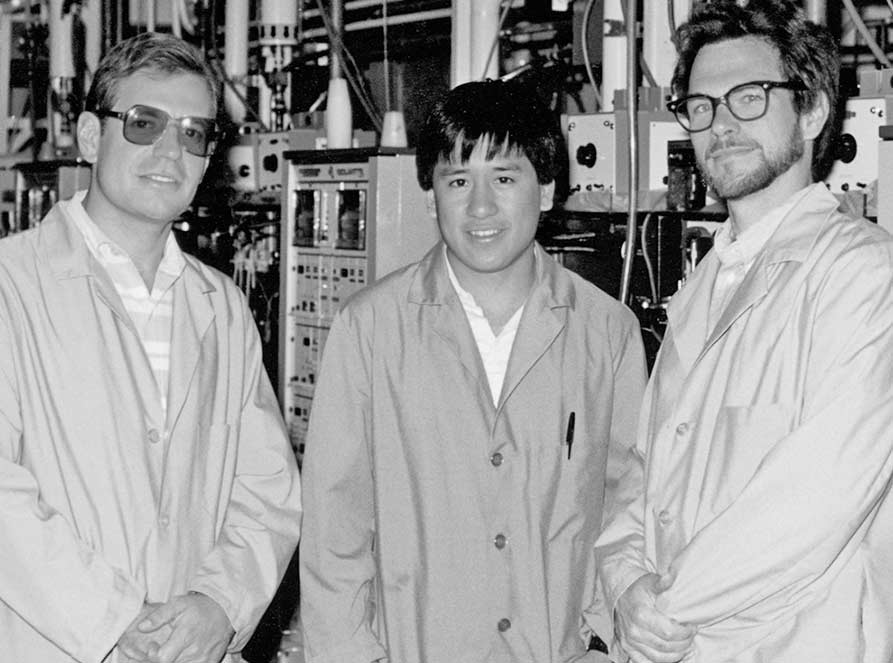

Black and white images (left to right)(top to bottom): A row of roller bottles in Building 6. John Fieschko, Ramon Seva, and Dennis Fenton in an early image with some fermentation equipment in a clinical manufacturing facility. Amgen staffer overseeing manufacturing of one of Amgen's early biotech medicines. This platform in Building 6 contained the cell culture media tanks used in manufacturing Amgen’s first biotech medicine. Amgen's first medicine in a roller bottle. Fill and finish facility, Puerto Rico.